Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

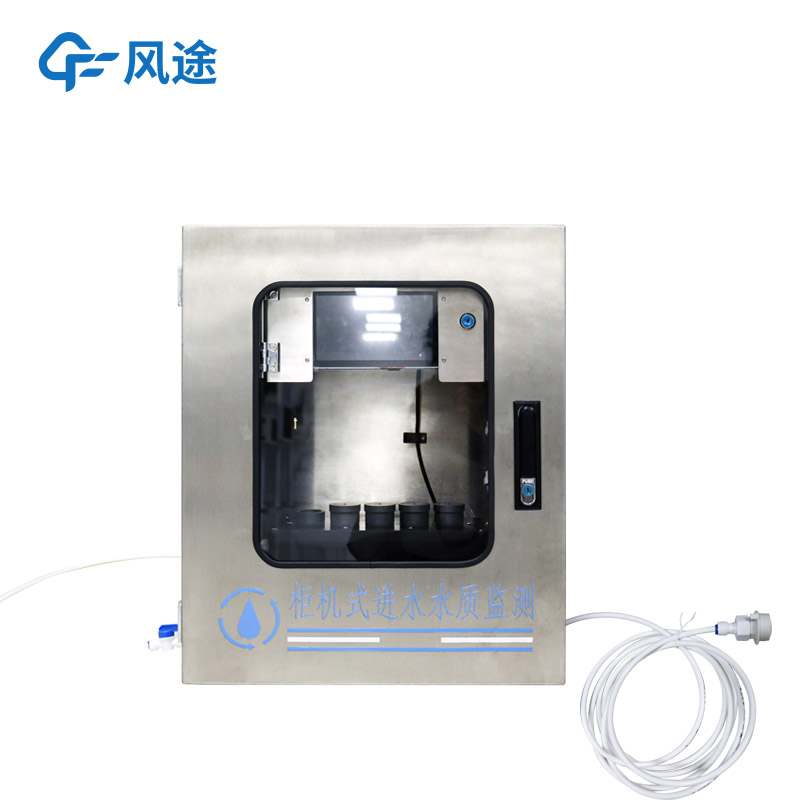

Model:FT-GSZ

Brand:tianyi

1.Water Quality Monitoring Station Secondary Water Product Introduction

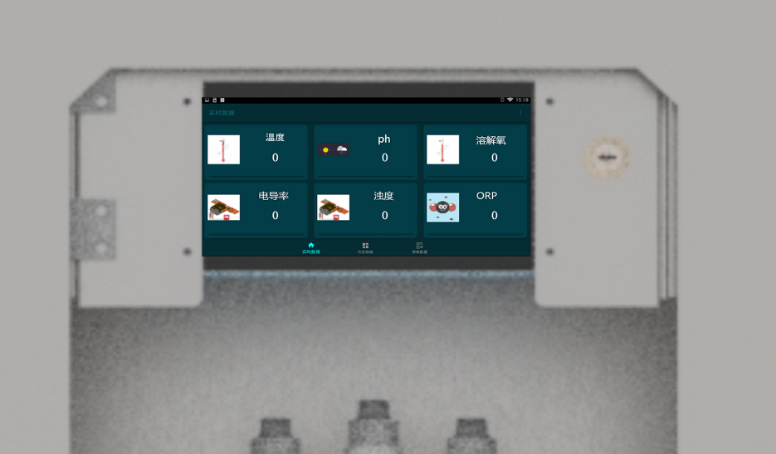

Water Quality Monitoring Station Secondary Water is used to monitor the pH, dissolved oxygen, conductivity, turbidity, ORP, temperature and other parameters of secondary water.

1.1 Overview

The GSZ water quality station is a comprehensive sensor acquisition, display and analysis system based on the Internet of Things technology.It is a water quality monitoring micro system.It consists of a steady-flow exhaust unit, an analysis and testing unit, a system control unit and a remote communication unit.It has complete power supply, lightning protection, network communication and other functions.

1.2 Product Positioning

GSZ This equipment is used in a pipe pressure environment for water supply end <0.3Mpa.It can be widely used for online monitoring of water quality such as urban or rural tap water plants, tap water water pipeline networks, tap water secondary water supply, user endings, indoor swimming pools, large-scale water purification equipment and direct drinking water.It is an indispensable online analysis equipment in the fields of water plant production process control, water conservancy and water management, sanitation supervision, etc.

1.3 Functions and Features

GPRS networking 4G

Supports extended RJ45 networking

Support extended sensor remote transmission

Supports LED screen display 7.0-inch touch control screen

Supports extended Android screen display and storage

Extended Android screen supports 2G data storage and USB data export

Supports RS485 modbus-RTU protocol slaves

Supports multi-channel RS485 modbus-RTU sensor extension

Supporting IoT data display, storage and analysis platforms

The platform supports TCP short links, HTTP protocol and other protocol data forwarding

2.Water Quality Monitoring Station Secondary Water composition

2.1 Composition unit

The water supply water quality monitoring micro system consists of a power supply unit, an analysis and testing unit, a display unit, a water pump unit, a remote communication unit and an integrated box main unit.

2.1.1 Power supply unit

Power adapter AC220 to DC12V/3A.

2.1.2 Analysis and Test Unit

The analysis and testing unit is mainly composed of pH, dissolved oxygen, conductivity, turbidity, ORP, and temperature sensors, and is fixed to the flow cell by threads or tight fixing parts.The main parameters of the sensor are as follows:

Technical parameters

| Serial number | Sensor Type | Measurement range | Measurement principle | Measurement accuracy |

| 1 | temperature | 0~50℃ | High-precision digital sensor | ±0.3℃ |

| 2 | pH | 0~14 (ph) | Electrochemistry (salt bridge) | ±0.1PH |

| 3 | Dissolved oxygen | 0~20mg/L | Fluorescence life method | ±2% |

| 4 | Conductivity | 0~5000uS/cm | Contact electrode method | ±1.5% |

| 5 | Turbidity | 0~40NTU (select) | Scattering light method | ±1% |

| 6 | ORP | -1500mv~1500mv | Electrochemistry (salt bridge) | ±6mv |

Note: The sensor cannot be installed inverted or horizontally when installed, and should be installed at least 15 degrees above the angle of inclination.

The working environment of the above water quality sensor is 0-50℃, <0.3Mpa.

2.1.3 Display Unit

Multi-parameter monitor, installed at the cabinet door, perform data acquisition, analysis, display, communication, and data storage operations.

Android version: 4.4.2·CPU: Quad-core Cortex™-A7·RAM/ROM: 512M/4G·Screen: 7-inch capacitor touch screen·Power supply: 12V/1A·Support USB disk expansion, support memory card expansion

2.1.4 Remote communication

RS485 interface MODBUS-RTU communication protocol factory equipment address 6 decimal support 03 function code reading data

| parameter | Decimal address | Hexadecimal address | Data Type |

| Parameter 1 | 40001 | 0x0000H | 16-bit integer |

| Parameter 2 | 40002 | 0x0001H | 16-bit integer |

| Parameter 3 | 40003 | 0x0002H | 16-bit integer |

| Parameter 4 | 40004 | 0x0003H | 16-bit integer |

| Parameter 5 | 40005 | 0x0004H | 16-bit integer |

| Parameter 6 | 40006 | 0x0004H | 16-bit integer |

Arrange in order

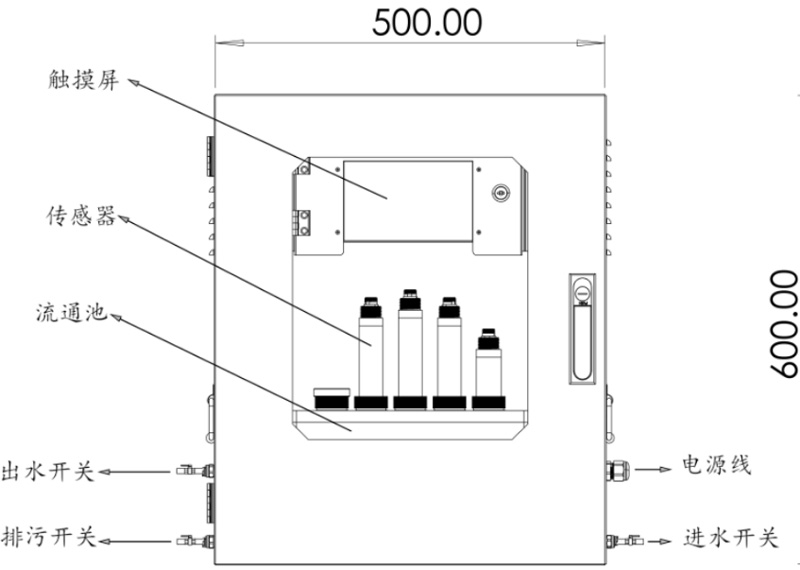

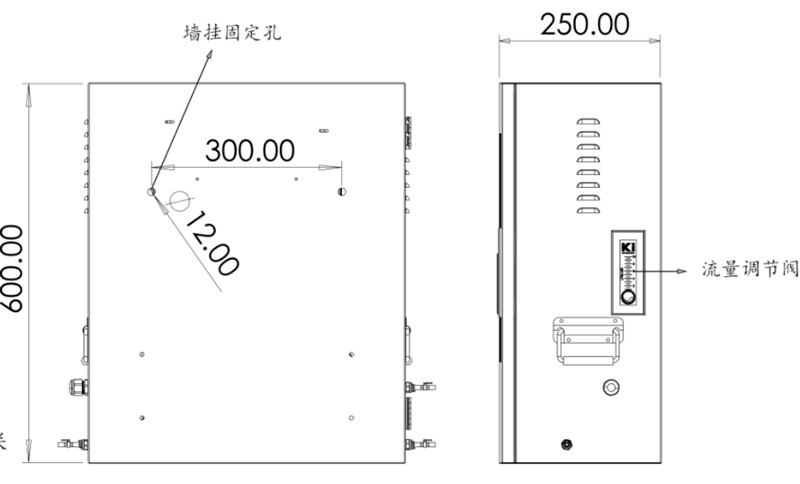

2.1.5 Equipment box main unit

| Product Name | GSZ |

| Installation method | The cabinet floor is installed and the base is installed. |

| External dimensions | 600X500X250mm |

| Housing material | 304 stainless steel. |

| Protection level | IP54 |

| powered by | AC220V; Internal power adapter AC220 to DC12V/3A |

| Water inlet | 2-point water purifier PE pipe with outer diameter φ6.5, flow rate 500mL/min, pressure 0.1-0.2MPa |

| Water outlet | 2-point water purifier PE pipe with outer diameter φ6.5, flow rate 400mL/min |

| Sewage outlet | 2-point water purifier PE pipe with outer diameter φ6.5, flow rate of 100mL/min (can also be manually discharged regularly) |

| Supporting sensor (optional) |

PH: 0-14 Dissolved oxygen: 0-20mg/L Turbidity: 0-40NTU Conductivity: 0-5000us/cm Temperature: 0°C ~ 50°C |

3.Water Quality Monitoring Station Secondary Water Product Size

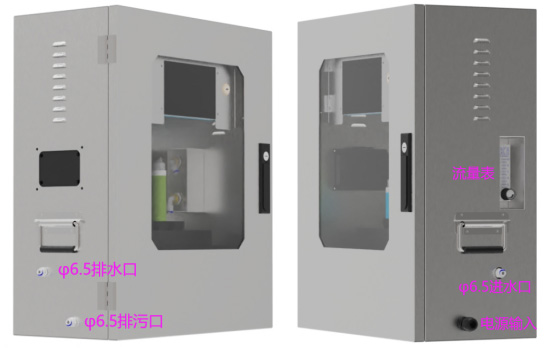

Water Quality Monitoring Station Secondary Water Front View

Water Quality Monitoring Station Secondary Water Side View

4.Water Quality Monitoring Station Secondary Water equipment installation

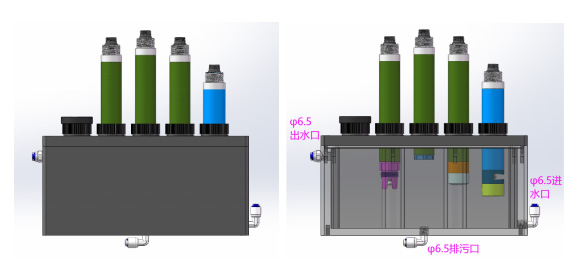

Overall equipment diagram

Internal measurement unit diagram

5.Water Quality Monitoring Station Secondary Water Maintenance

When you use it for the first time or not reuse it for a long time,

The pH-sensitive bulb and reference fluid should be immersed in 3.3 mol/L KCI solution for more than 2 hours.

When using, wash and wipe dry with deionized water (or distilled water) to prevent impurities from being brought into the liquid to be tested.1/3 of the sensor should be inserted into the liquid to be tested.The terminal part should be kept clean and dry.When the sensor is not in use, it should be cleaned.Insert the protective cover with 3.3mol/L KCI solution, or insert the sensor into a container with 3.3mol/L KCI solution.Check whether the terminals are dry.If there are any stains, wipe them with anhydrous alcohol and continue to use them after drying.The sensor should avoid long-term soaking in deionized water, protein solutions, strong acid and alkali solutions, and acid fluoride solutions, and prevent contact with silicone grease.The sensor that has been used for a long time may become translucent or contain deposits.At this time, it can be washed with dilute hydrochloric acid and rinsed with water.When the sensor has a long service life, it can be calibrated and corrected by matching the instrument.When the sensor is maintained and maintained by the above method, it means that the sensor has failed.Please replace the sensor.

Electrodes with conventional conductivity need to be periodically cleaned and calibrated, and the maintenance cycle is determined by the customer according to their working conditions.Conventional electrode cleaning methods: Use a soft brush to remove attachments (be careful to avoid scratching the electrode surface), then clean with distilled water, and then perform calibration operations.

The ORP-sensitive bulbs and reference fluids should be immersed in 3.3 mol/L KCI solution for more than 2 hours.

When using, wash and wipe dry with deionized water (or distilled water) to prevent impurities from being brought into the liquid to be tested.1/3 of the sensor should be inserted into the liquid to be tested.The terminal part should be kept clean and dry.When the sensor is not in use, it should be cleaned.Insert the protective cover with 3.3mol/L KCI solution, or insert the sensor into a container with 3.3mol/L KCI solution.Check whether the terminals are dry.If there are any stains, wipe them with anhydrous alcohol and continue to use them after drying.The sensor should avoid long-term soaking in deionized water, protein solutions, strong acid and alkali solutions, and acid fluoride solutions, and prevent contact with silicone grease.If the platinum sheet of the electrode is stained with grease, you can use degreased cotton to dip acetone or alcohol and gently wipe it clean.If the dirt is insoluble inorganic substances, you can use 30-50% hydrochloric acid to wipe it once a day with clean high-end toilet paper.When the sensor has a long service life, it can be calibrated and corrected by matching the instrument.When the sensor is maintained and maintained by the above method, it means that the sensor has failed.Please replace the sensor.

External surface of dissolved oxygen sensor: Rinse the external surface of the sensor with clean water.If there is still dirt residue,

Please wipe it with a moist soft cloth.For some stubborn dirt, you can add some household detergent solution to the water to clean it.Fluorescent film head surface: If there is dirt on the surface of the fluorescent film head, rinse with clean water or gently wipe with a soft cloth.Pay attention to avoid scratches in the measurement area and affecting the measurement accuracy when cleaning.Avoid sunlight or strong light on the inner surface of the fluorescent film.Do not touch the fluorescent film with your hands or sharp objects.When using it, avoid bubbles attached to the surface of the fluorescent film.

Turbidity sensor maintenance: If the sensor needs to be cleaned, you can use warm water and an appropriate amount of detergent to clean it.

Note: Avoid strong vibration damage ring with light-transmitting glass in front of the light-transmitting glass, and do not scratch with hard products.

Under the general trend of technology empowering agriculture, Agricultural meteorological stations are gradually becoming key facilities for ensuring agricultural production and promoting the modernization of agriculture.It can conduct real-time and precise monitoring of various meteorological...

In daily life, whenever we easily press the switch and the lights turn on instantly and the electrical appliances operate smoothly, few people will think deeply that behind this seemingly ordinary power supply, there is actually a huge and complex technological system operating stably. Among the man...

The Micro water quality station is a highly integrated professional device that combines various functions such as sensor technology, data collection and processing systems, and communication modules. Its working principle is based on the monitoring of various parameters in the water body by differe...

In the agricultural field, the traditional extensive irrigation method relying on experience is likely to cause either water resource waste or insufficient irrigation. With the rise of precision agriculture, different crops have varying requirements for soil temperature and humidity at different gro...