Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-HS1

Brand:tianyi

1.Photovoltaic module dust product overview

Photovoltaic module dust reduces the radiation reaching the solar cells, reducing electrical energy output by partially blocking solar irradiance.

Pollutants on the glass of solar modules are one of the main problems that rapidly affect photovoltaic power plants, which will reduce power generation efficiency and cost-effectiveness.Dust pollution will significantly reduce the power generation of photovoltaic power plants, which is estimated to be at least more than 5% per year.Using blue light pollutant light closed-loop measurement (OMBP) technology, it can be easily installed into new or existing photovoltaic arrays and integrated into power station management systems.The device is mounted on the frame of the photovoltaic panel.By continuously measuring the transmission loss caused by contaminants on the glass, the reduction in sunlight reaches the solar module is calculated.

By measuring the ratio of pollutants (SR), it is converted into loss of power generation in real time.This allows operation and maintenance personnel to know when the contaminants have reached the critical point and it is necessary to start the cleaning process.The product does not require maintenance and simply cleans the same way when cleaning the surrounding components.

Because large photovoltaic power stations have different pollution rates throughout the park, multi-point measurement is required in the IEC 61724-1 standard.Compared to traditional systems, the cost of procurement, installation and maintenance is much lower, making it more economical, so that cleaning can be planned at the time and place of need.

2.The impact of dust on photovoltaic power generation

Everyone knows that dust covers components, forming a shading phenomenon, which directly leads to a decrease in the power output of components.Moreover, long-term adherence of dust has a certain corrosion effect on the components.At the same time, dust always exists to cause heat spots in the components, further reducing the output power of the components, and even affecting the lifetime of the components.Moreover, the heat spot effect is irreversible to the components.Once there is no means of compensation, you can only choose to replace the components.Otherwise, it will affect the power generation and may also bring safety hazards to the power station.

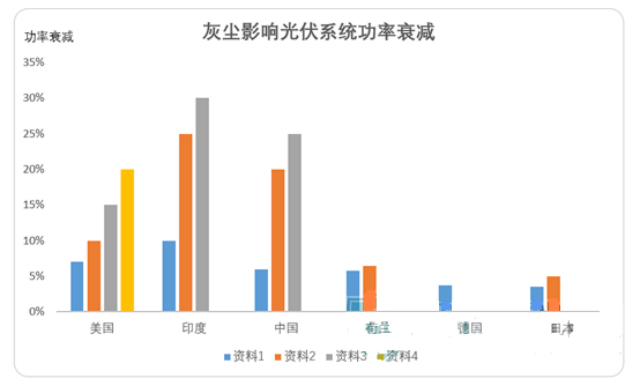

Several domestic and foreign survey institutions conducted research on the power attenuation of dust in the photovoltaic system, and the data were obtained as shown in Figure 1.

From the above figure, we can see that the output power of my country's photovoltaic system is affected by dust on average about 20%.

The impact of dust on photovoltaic power generation is mainly attributed to the following three aspects:

1.Temperature influence

At present, photovoltaic power stations mostly use silicon-based solar cell modules.This module is very sensitive to temperature.As dust accumulates on the surface of the module, the thermal transfer resistance of the photovoltaic module increases, becoming a heat insulation layer on the photovoltaic module, affecting its heat dissipation.

Studies have shown that the temperature of solar cells increases by 1℃ and the output power drops by about 0.5%.Moreover, under long-term sunlight, the covered part of the battery module has a heating speed that is much higher than that of the uncovered part, causing burnt dark spots to appear too high.

Under normal illumination, the covered battery panel will change from a power generation unit to a power consumption unit, and the masked photovoltaic cell will become a load resistor that does not generate electricity, consuming the power generated by the connected battery, that is, heating, which is the heat spot effect.This process will aggravate the aging of the panel and reduce the output, and in severe cases it will cause components to burn.

2.Blocking the impact

When dust adheres to the surface of the battery panel, it will block, absorb and reflect light, the most important of which is the blocking effect of light.The reflection absorption and occlusion effect of dust particles on light affects the absorption of light by photovoltaic panels, thereby affecting the efficiency of photovoltaic power generation.

Some studies have pointed out that dust deposits on the light-receiving surface of the panel assembly, which first causes the light transmittance on the surface of the panel to decrease; secondly, it changes the incidence angle of some light, causing the light to propagate unevenly in the glass cover.

Studies have shown that under the same conditions, the output power of clean panel components is at least 5% higher than that of dust-abundant components, and the higher the dust-abundant, the greater the output performance of the component.

3.Corrosion impact

Most photovoltaic panel surfaces are made of glass, and the main components of glass are silica and limestone.When wet acidic or alkaline dust adheres to the surface of the glass cover, the components of the glass cover can react with acid or alkali.

As the time of glass increases in acidic or alkaline environments, the glass surface will slowly be eroded, thus forming potholes on the surface, resulting in diffuse reflection on the surface of the cover plate and the uniformity of propagation in the glass is destroyed.The rougher the cover plate of the photovoltaic module, the smaller the energy of the refracted light, and the energy actually reaches the surface of the photovoltaic cell, resulting in a decrease in the power generation of the photovoltaic cell.And rough, viscous surfaces with adhesive residues are more likely to accumulate dust than smoother surfaces.Moreover, the dust itself will also absorb dust.Once the initial dust exists, it will cause more dust to accumulate, which will accelerate the attenuation of the power generation of the photovoltaic cell.

3.Photovoltaic module dust product features

1.Real-time data monitoring: Four types of data can be collected and analyzed, pollution ratio, clean ratio, dust thickness, and backboard temperature.The pollution ratio and clean ratio are used to use a dual probe.

The mean data calculation mode ensures accurate and reliable data.

2.Technology-based acquisition instrument: The dust environment data acquisition instrument adopts a new generation of 32-bit MCU processor, and integrates high-precision 4G and Bluetooth digital chips on-board, which can enable the collected data to be sent to the data monitoring platform through wired or wireless modes.

3.Innovative blue light technology: adopts a new generation of blue light pollutant light closed-loop measurement (OMBP) technology, which can effectively ensure high-precision dust data detection and effectively prevent sunlight from interfering with closed-loop data acquisition by optical circuits.It can be used for a long time in all weather conditions, which is better than the provision required by the IEC 61724-1 standard that can only be effectively monitored for three hours at 11:00 to 13:00 per day.

4.Smart power station cleaning: a new generation of IoT management and control module is built-in, with four control modes: normally open and normally closed, cycle control, time control, and manual control.According to the set pollution threshold and control mode, the cleaning robot or IoT control equipment can be linked to automatically clean the dust on the battery panel to ensure the high-efficiency power generation needs of the photovoltaic power station.

5.Accuracy self-calibration: There is a one-click accuracy self-calibration button integrated on the device.The acquisition accuracy of the device will decrease depending on different application environments and different usage time.The self-calibration button can automatically recalibrate the blue light monitoring circuit to ensure accurate and reliable data observation.

6.Green power management: This data collector can use two power supply modes: AC220V and DC12V.It also integrates a new generation of green power management modules to achieve intelligent switching between AC and DC power supply.

4.Photovoltaic module dust technical indicators

| Serial number | Product Performance | Imported products | Our products |

| Observation indicators | |||

| Measurement parameters | Pollution ratio, cleanliness ratio, dust thickness | ||

| Measurement range | Pollution ratio 50-100%; dust thickness 0-10mm | ||

| Measurement accuracy of pollution ratio | Measurement range 90-100% | Measurement accuracy ±1% | |

| Measurement range 80-90% | Measurement accuracy ±2% | ||

| Measurement range 50-80% | Measurement accuracy ±5%, processed by internal precision algorithm | ||

| Dust thickness accuracy | Dust thickness ±5% | ||

| PV backplane temperature (optional) | Measuring range -50~150℃ | Measurement accuracy ±0.3℃ | |

| Stability | Automatic calibration, better than 1% of the full range per year | ||

| Communication method | Wired RS485, wireless 4G\Bluetooth | ||

| Control method | Normally open and closed, cycle control, time control, manual control | ||

| 1 | Implementation standards | IEC61724-1:2017 | IEC61724-1:2017 |

| 2 | Technical Principles | Blu-ray technology | Blue light diffuse scattering closed loop technology |

| 3 | Dust indicators | Propagation loss rate (TL)\pollution rate (SR) | Propagation loss rate (TL)\pollution rate (SR) |

| 4 | Monitoring probe | Dual probe mean data | Dual probe mean data |

| 5 | Calibration of photovoltaic panels | 1 piece | 2 pieces |

| 6 | Observation time | Valid data 24 hours a day | Valid data 24 hours a day |

| 7 | Test interval | 1min | 1min |

| 8 | Monitoring software | have | have |

| 9 | Threshold alarm | none | Upper, lower limit, linkage secondary equipment |

| 10 | Communication method | RS485 | RS485\Bluetooth\4G |

| 11 | Communication protocol | MODBUS | MODBUS |

| 12 | Supporting software | have | have |

| 13 | Component temperature | Platinum resistor | PT100 Class A Platinum Resistor |

| 14 | Working power supply | DC 12~24V | DC 9~36V |

| 15 | Equipment power consumption | 2.4W @ DC12V | 2W @ DC12V |

| 16 | Operating temperature | -20~60˚C | -40~60˚C |

| 17 | Protection level | IP65 | IP65 |

| 18 | Product size | 990×160×40mm | 900×160×40mm |

| 19 | Product weight | 4kg | 3.5 kg |

| 20 | Product price | International price system | China's price system |

Some enterprises, in order to reduce wastewater treatment costs, secretly discharge untreated sewage directly into the external environment or municipal pipelines through illicitly installed concealed pipes. For example, a company in an industrial park discharged high-concentration phenol-containing...

Negative oxygen ions are hailed as “air vitamins” and are extremely beneficial to human health. As people’s awareness of health and pursuit of tourism quality have improved, scenic areas’ implementation of negative oxygen ion detection projects can not only create a healthy and comfortable touri...

In the field of meteorological monitoring, TianYi has launched a series of Handheld Weather Stations, among which the FT-SQ5 model has attracted much attention. It integrates the monitoring functions of multiple key meteorological elements. With high-precision sensors and intelligent chips, it can a...

In the road structure system, from top to bottom are the surface course (with a thickness of about 15 centimeters), the base course (with a thickness of about 30 centimeters), the cushion course (with a thickness of about 25 centimeters), and the subgrade. The highway subgrade can encounter problems...