Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-S10

Brand:tianyi

one.Suspended Solids Sensor Application Environment Description

Suspended Solids Sensor is designed to measure Total Suspended Solids (TSS) in various solutions for use in various industrial wastewater treatment systems.The scattering or absorption properties of light are used to measure the concentration of suspended solids in water.It has high sensitivity, fast response and real-time monitoring capabilities, and is widely used in water quality monitoring and sewage treatment.

Signal output: RS485 (MODBUS-RTU).Infrared LED light source, strong anti-interference ability.

Internal signal isolation technology has strong interference.

Good reproducibility, thermal stability, low drift, small size, fast response speed

Easy to install, simple, 3/4NPT pipe thread, easy to install or install in sinking or stable performance in pipes and tanks, long service life

IP68 waterproof standard

two.Suspended Solids Sensor Technical Performance and Specifications

1.Suspended Solids Sensor Technical Parameters

| Measurement principle | Scattering light method |

| Signal method | RS485 (MODBUS-RTU) |

| Measurement range | 0~2000mg/L |

| Measure resolution | 0.1mg/L |

| Measurement accuracy | ±5% (depending on sludge homogeneity) |

| Housing material | Glass and ABS |

| Cable length | Standard 5 meters |

| Power supply voltage | 12-24VDC (0.4W@12V) |

| Calibration method | Two-point calibration |

| Measurement environment | Temperature 0~50℃ (no freezing), < 0.2MPa |

| Waterproof grade | IP68 |

| Installation method | Immersive mounting, NPT3/4 thread |

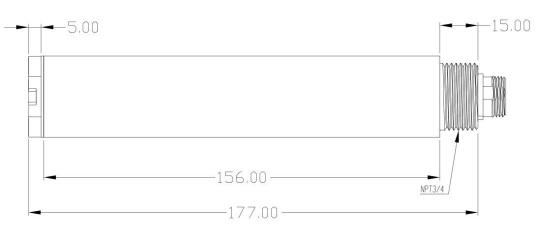

2.Suspended Solids Sensor Size Diagram

The sensor connector is M12 aviation plug connector 5-core mother seat

three.Suspended Solids Sensor Installation and Electrical Connection

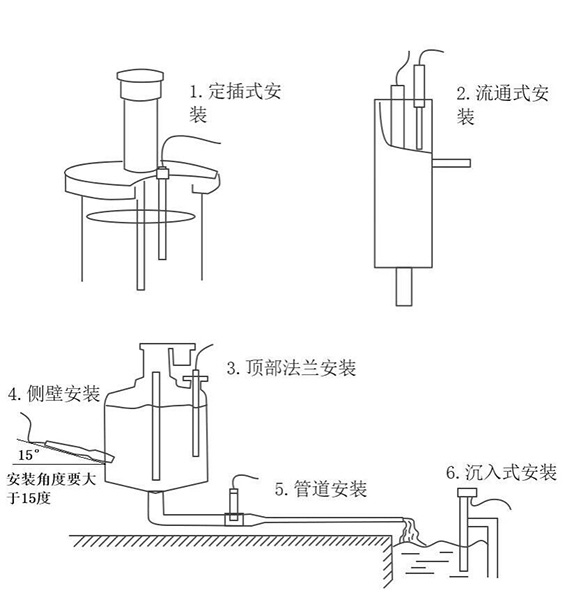

1.Suspended Solids Sensor installation

Note: The sensor cannot be installed inverted or horizontally when installed, and should be installed at least 15 degrees above the angle of inclination.

2.Suspended Solids Sensor electrical installation

The cable is a 5-core shielded wire, and the line sequence is defined:

Brown - Power cord (12~24VDC) Black - Ground cord (GND)

Green-485B Yellow-485A

Before powering on, carefully check the wiring sequence to avoid unnecessary losses caused by wiring errors.

Four.Suspended Solids Sensor Maintenance and Maintenance

1.Use and maintain

The sensor's measurement window is one of the key components to ensure the normal operation and accurate measurement of the sensor.Its cleaning requirements are crucial to ensure the accuracy and reliability of the measurement.

1.1 Maintenance method

1.Regular cleaning: The measurement window should be cleaned regularly to remove dirt, sediment and other impurities attached to the surface.The cleaning frequency depends on the measurement environment, but daily or weekly cleaning is generally recommended.

2.Use gentle detergent: When cleaning, you should choose gentle detergents and avoid using cleaners containing abrasives or acid-base ingredients to prevent damage to the surface of the measurement window.

3.Soft cloth or sponge: During the cleaning process, use a soft cloth or sponge to gently wipe the surface of the measurement window to prevent scratches or wear.

4.Avoid direct contact: Avoid touching the measuring window surface directly during cleaning to reduce fingerprint and grease contamination.

5.Rinse: After cleaning is completed, the measurement window should be thoroughly rinsed with clean water to ensure that residual detergent and dirt are removed.

6.Dry: After cleaning, gently wipe the surface of the measuring window using a dry soft cloth to remove water stains and ensure complete dryness.

7.Regular inspection: Regularly check the surface of the measurement window for damage or wear to keep the sensor running normally.

8.Avoid exposure to chemicals and high temperature environments: Avoid exposing the measurement window to harmful chemicals or high temperature environments to prevent damage or corrosion to its surface.

When the sensor has a long service life, it can be calibrated and corrected by matching the instrument.When the sensor is maintained and maintained by the above method, it means that the sensor has failed.Please replace the sensor.

five.Notes on Suspended Solids Sensor

1.The measurement window contains glass components, so use sharp or hard objects to scratch the surface to prevent scratches and damage.

2.It contains sensitive optical components and precision electronic equipment inside to avoid exposing the sensor to violent vibration or impact, so as to prevent the displacement or damage of the optical parts and electronic equipment.No maintenance is required inside the equipment.

3.When not in use, appropriate dust covers or covers should be used to protect the optical parts from dust and contaminants.

The measurement of wind speed and direction is of great importance in many fields, such as weather forecasting, high - speed railways, wind power generation, industrial and agricultural production, and scientific research.In the traditional meteorological field, the measurement of wind speed and dir...

In the field of meteorological monitoring, TianYi has launched a series of Handheld Weather Stations, among which the FT-SQ5 model has attracted much attention. It integrates the monitoring functions of multiple key meteorological elements. With high-precision sensors and intelligent chips, it can a...

Although traditional mechanical wind speed and direction meters have, to some extent, met basic requirements, they have limitations in terms of accuracy, response speed, and reliability. With the advancement of technology, the 3D Ultrasonic Anemometer based on the time - difference method has been d...

Explosion - proof weather stations are meteorological monitoring devices specifically designed to operate in hazardous environments. With the development of industries such as manufacturing, military, and chemical, the demand for explosion - proof weather stations has been growing steadily. The main...